What factors will affect the feeding accuracy of square tube?

- Share

- publisher

- youyouxiaotian

- Issue Time

- Dec 2,2022

Summary

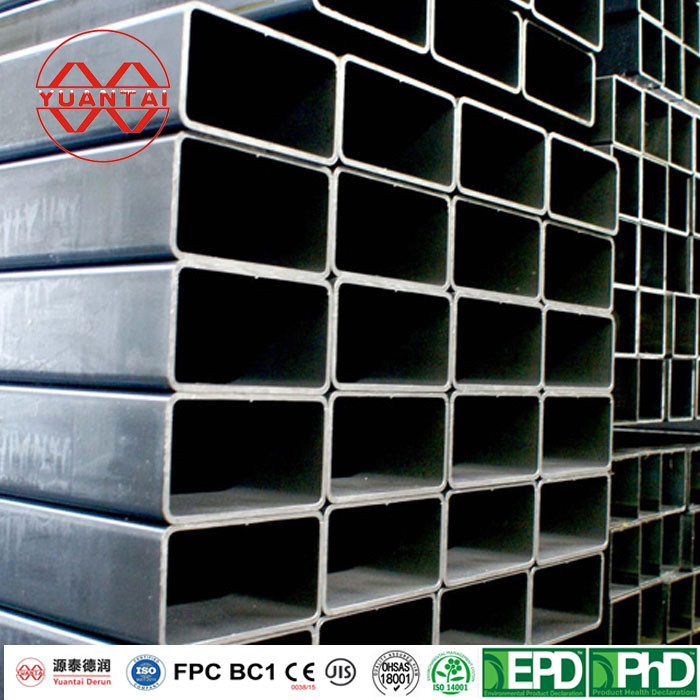

During the production of square and rectangular tubes, the feeding accuracy directly affects the accuracy and quality of the formed products. Today we will introduce seven factors that affect the feeding accuracy of rectangular tube:

What factors will affect the feeding accuracy of square tube?

During the production of square and rectangular tubes, the feeding accuracy directly affects the accuracy and quality of the formed products. Today we will introduce seven factors that affect the feeding accuracy of rectangular tube:

(1) The center line of the feeding device and the center line of the stamping machine must be set on the same line. If it is not in a straight line, when the uncoiled material is sent to the mold, it is inclined relative to the mold. The material guidance inside the mold and the side guidance of the feeding device will have great resistance, which will greatly reduce the accuracy of feeding.

(2) The ripple shape in the amplitude direction of the coil must be small, and the wave bulge in the 2000mm length range in the width direction of the coil must also be less than 2mm. The bulge will also increase with the increase of the plate thickness. In serious cases, there will be more than 5mm bulge within the length range of 2000mm, so the square tube material cannot be fed.

(3) Compared with the coil with very smooth surface, the friction coefficient between the square steel plate with rough surface and the roller of the feeding device is higher, so the feeding accuracy will be improved accordingly. It should be noted that the rolled steel plate with rough surface will form very small concave convex on the material surface during cold rolling extension. These rough surfaces will cause residual rolling oil and facilitate deep drawing.

(4) The gear backlash driving the feeding roller is relatively small, and the servo motor driving the feeding roller can flexibly and appropriately accelerate and decelerate.

(5) The rolling oil film also affects the accuracy of square tube. If the rolling oil is placed for too long after rolling, it will dry and solidify, and the material will slide with the feeding roller when feeding, which will reduce the accuracy of feeding.

(6) When the coiled material is sheared from a very wide material, the amplitude of the material sheared due to the accuracy and stiffness of the shearing device will have positive and negative errors. When passing through the guide column of the die, if the material is too narrow, there will be a gap and shake, which will reduce the accuracy of feeding. When passing through the guide column of the die, the material will be compressed and deformed if it is too wide, which will also seriously reduce the feeding accuracy.

(7) The coiled materials of square and rectangular tubes are all rolled from very wide rolled steel plates. The accuracy near the middle is relatively good. The two ends of the width direction are gradually thinner, and the accuracy of the thickness is significantly worse. At this time, coiled materials with poor width accuracy will also affect the feeding accuracy.