Connection method of q355b rectangular tube

- Share

- From

- www.ytdrintl.com

- publisher

- youyouxiaotian

- Issue Time

- Sep 6,2022

Summary

In the prior art, a two-step method is used to connect q355b rectangular tubes.

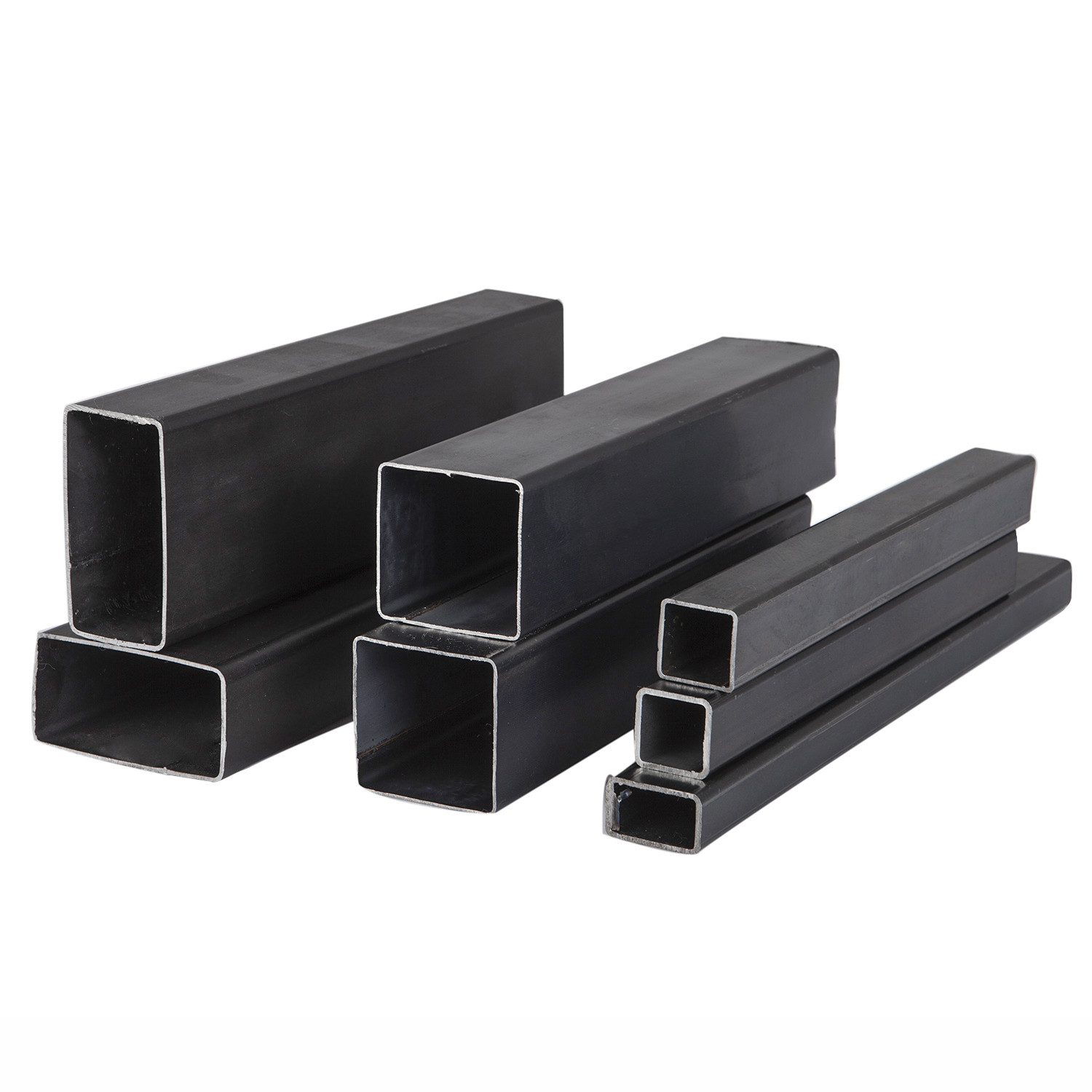

Connection method of q355b rectangular tube

In the prior art, a two-step method is used to connect q355b rectangular tubes. First, the square tube is pressed out of the joint, and then the joint of the two tubes is connected with a docking mechanism. This requires a lot of human resources and has low R & D and production power. The technical problem to be solved by the utility model is to provide a q355b rectangular tube docking mechanism, which solves the technical problem that the square tube docking in the prior art requires a large number of human resources and has a low level of R & D and production power.

In order to solve the above technical problems, the technical solution of the utility model is:

A square tube docking mechanism comprises a workbench and a docking mechanism, and the docking mechanism is arranged on the workbench; The docking mechanism comprises a first pushing mechanism, a second pushing mechanism and a crimping mechanism;

The first pipe pushing mechanism comprises a receiving pipe, the bottom of the receiving pipe is provided with a pipe groove, a pipe box is arranged below the pipe groove, a pipe lifting device is arranged at the bottom of the pipe box, and a pneumatic pushing plate is arranged at the end of the receiving pipe. The pneumatic push plate is connected with the cylinder. The front end of the pneumatic push plate is provided with a cushion pad. The lifting device is controlled by the cylinder. The second pipe pushing mechanism comprises a receiving pipe, the bottom of the receiving pipe is provided with a pipe slot, a pipe box is arranged below the pipe slot, a pipe lifting device is arranged at the bottom of the pipe box, and a pneumatic pushing plate is arranged at the end of the receiving pipe. The pneumatic push plate is connected with the cylinder. The front end of the pneumatic push plate is provided with a cushion pad. The lifting device is controlled by the cylinder. The center of the workbench is provided with an expansion plate.

According to the technical scheme of the present invention, since two pushing mechanisms are provided, two square tubes can be pushed relatively. One of the pushing mechanisms is provided with a crimping mechanism at the end near the middle, so that the crimping mechanism can complete the docking before the square tube is docked, without processing the square tube. The ring ratio reduces the labor cost, realizes automation, and improves the manufacturing power level.