Tianjin yuantaiderun group undertakes various special-shaped pipes and annealing services

- Share

- From

- www.ytdrintl.com

- publisher

- youyouxiaotian

- Issue Time

- Aug 5,2021

Summary

Tianjin yuantaiderun group undertakes various special-shaped pipes and annealing services

TIANJIN YUANTAIDERUN GROUP UNDERTAKES VARIOUS SPECIAL-SHAPED PIPES AND ANNEALINGSERVICES

Tianjin yuantai running Group tiene 18 filiales de propiedad total de personas jurídicas, de las cuales Tianjin yuantai Technology Development Co., Ltd. Comenzó en 2014, con el fin de producir el raro mercado de tubos cuadrados de gran calibre y paredes súper gruesas. Este tipo de tubo no estándar toma el tubo de soldadura de arco sumergido de costura recta o el tubo de acero sin soldadura como materia prima, a través de la extrusión secundaria de la materia prima en el tubo cuadrado que cumple con los requisitos de calidad. Además, Tianjin yuantai Technology Development Co., Ltd. También puede producir tubos rectangulares, octogonales, trapezoidales y otras especificaciones de tubos heterogéneos, y llevar a cabo procesos de templado y recocido, con el apoyo de técnicos profesionales y equipos, nuestro próximo objetivo es desarrollar tubos heterogéneos.

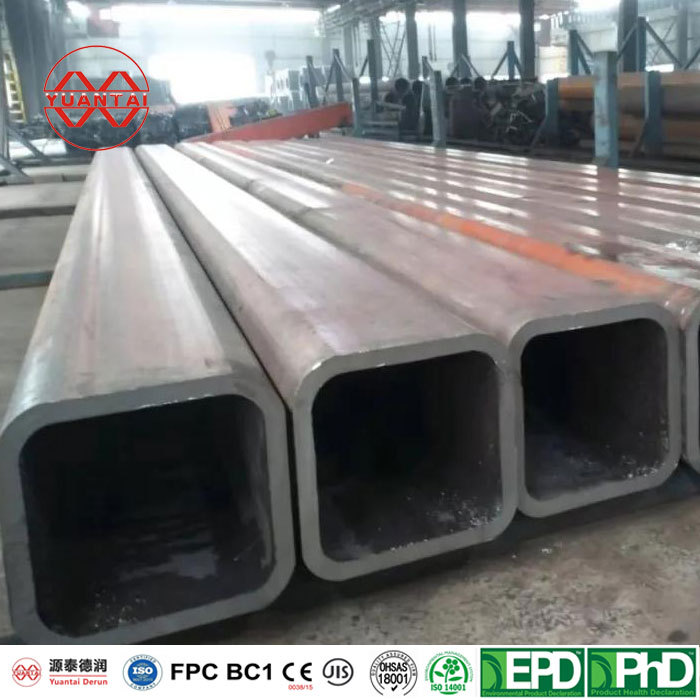

(the picture shows 500mm * 500mm * 36mm modified pipe produced by Yuantai Technology)

(the picture shows 500mm * 500mm * 36mm modified pipe produced by Yuantai Technology-Google building in Singapore)

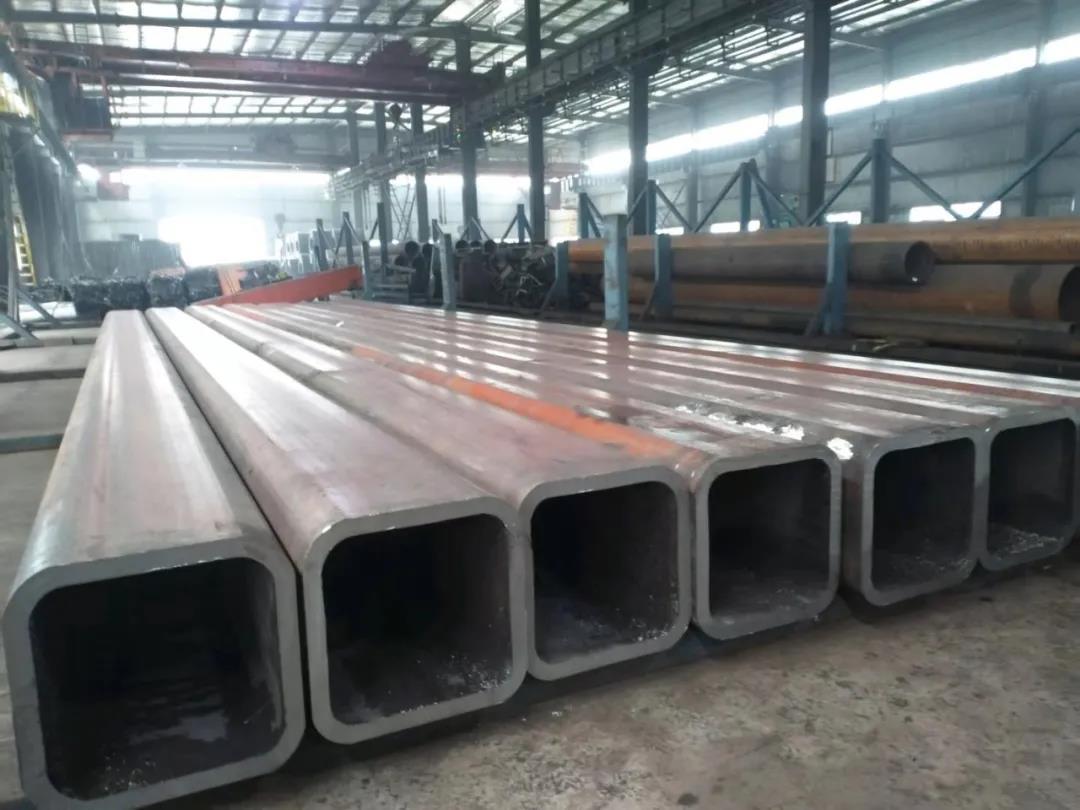

(the picture shows 900mm * 900mm * 25MM modified pipe produced by Yuantai Technology)

(the picture shows 900mm * 900mm * 25MM modified pipe produced by Yuantai Technology)

1、 Production specifications and technical standards

Tianjin Yuantai Technology Development Co., Ltd. has 4 production units and more than 50 employees, which undertake large-diameter thick wall rectangular tubes, seamless rectangular tubes, special-shaped tubes, hot-rolled rectangular tubes, square tube specifications of 80 * 80mm-1200 * 1200mm, rectangular tube specifications of 50 * 100mm-1200 * 1500mm, wall thickness of 2.75mm-50 mm, in accordance with the standard GB / t3091-2015, Any specification and material in this range (such as Q235 / q355 / Q390 / Q420 / Q460 / high strength steel / weathering steel, etc.) can be customized. Among them, the outgoing process of hot-rolled right angle pipe is particularly advanced. Two technical methods of on-line hot rolling four corners and overall heating are adopted, which has the advantages of both power saving and high efficiency.

Tianjin Yuantai Technology Development Co., Ltd. has 4 production units and more than 50 employees, which undertake large-diameter thick wall rectangular tubes, seamless rectangular tubes, special-shaped tubes, hot-rolled rectangular tubes, square tube specifications of 80 * 80mm-1200 * 1200mm, rectangular tube specifications of 50 * 100mm-1200 * 1500mm, wall thickness of 2.75mm-50 mm, in accordance with the standard GB / t3091-2015, Any specification and material in this range (such as Q235 / q355 / Q390 / Q420 / Q460 / high strength steel / weathering steel, etc.) can be customized. Among them, the outgoing process of hot-rolled right angle pipe is particularly advanced. Two technical methods of on-line hot rolling four corners and overall heating are adopted, which has the advantages of both power saving and high efficiency.

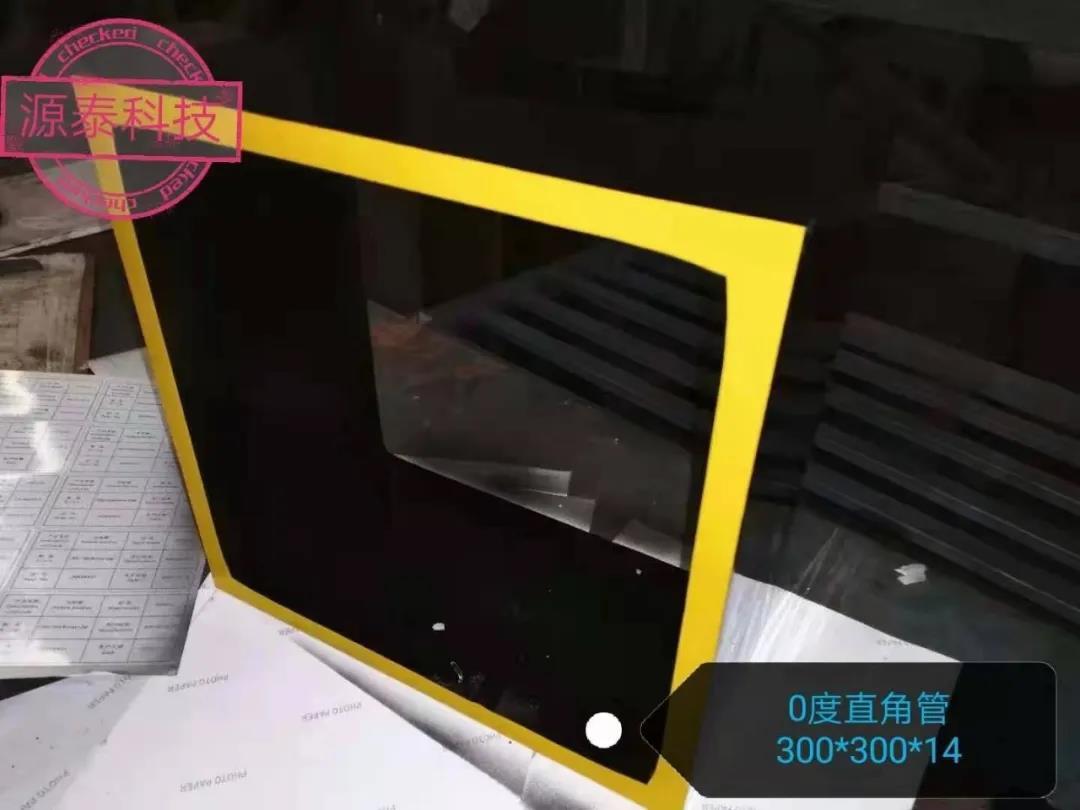

(the picture shows 300mm * 300mm * 14mm right angle pipe produced by Yuantai Technology)

(the picture shows 150mm * 400mm * 25MM right angle pipe produced by Yuantai Technology)

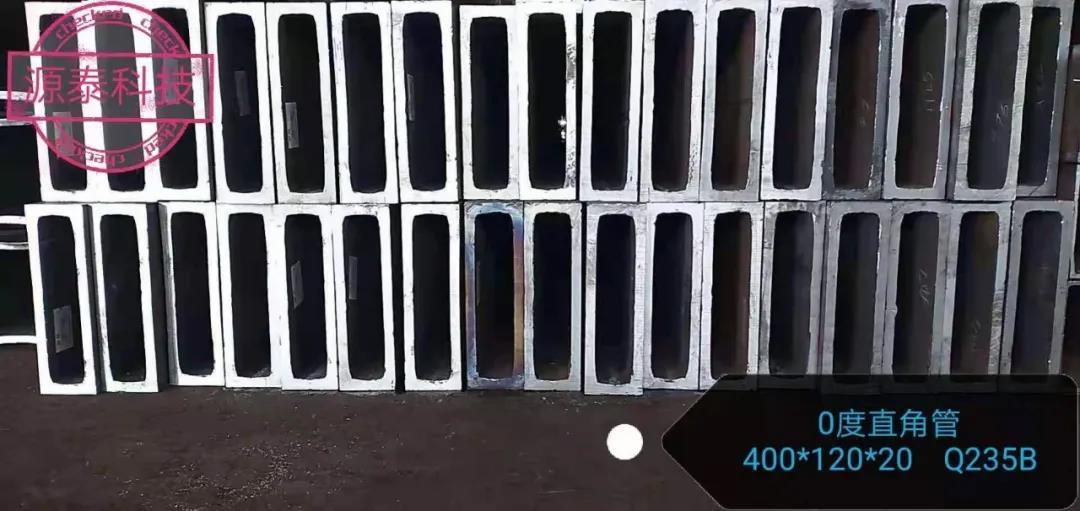

(the picture shows 120mm * 400mm * 20MM right angle pipe produced by Yuantai Technology)

(the picture shows 80mm * 240mm * 20MM right angle pipe produced by Yuantai Technology)

2、 Process flow

Inspection of round pipe (raw material) - feeding - hydraulic propulsion - roll extrusion (round square change) - Inspection of steel pipe (overall dimension, flatness, perpendicularity and R angle) - blanking (inspection of steel pipe straightness and twist) - shaping of mouth end (there will be deformation area at the head end during steel pipe deformation) - sawing and trimming - Inspection and spraying standard - Warehousing

Inspection of round pipe (raw material) - feeding - hydraulic propulsion - roll extrusion (round square change) - Inspection of steel pipe (overall dimension, flatness, perpendicularity and R angle) - blanking (inspection of steel pipe straightness and twist) - shaping of mouth end (there will be deformation area at the head end during steel pipe deformation) - sawing and trimming - Inspection and spraying standard - Warehousing

3、 Processing business

The main purpose of the new intelligent tempering furnace equipment of Tianjin yuantaiderun group is to remove the internal stress in the steel pipe. The methods of removing internal stress include natural aging and artificial aging. Natural aging is that the steel pipe is placed in the open field for more than half a year, and it will form slowly, so as to eliminate or reduce the residual stress. There are two methods of artificial prescription:

① Heat treatment to remove internal stress: heat the steel pipe to 550 ~ 650 ℃ for stress relief annealing, which saves time than natural aging and removes residual stress more thoroughly

② Vibration stress relief: in short, it is to eliminate the stress of steel pipe by vibration. VSR is to apply additional alternating stress or deformation to the workpiece by using the resonance of the workpiece. When the additional alternating stress is superimposed with the residual stress and absorbs energy through the internal friction of the material to reach or exceed a certain threshold value of the material, the workpiece will undergo micro or macro viscoelastic plastic mechanical deformation, so as to reduce and homogenize the residual stress in the workpiece and stabilize its dimensional accuracy.

The square rectangular tube after internal stress relief annealing ensures the mechanical properties, especially in the aspects of yield strength, tensile strength, elongation and impact compressive capacity, and realizes the effect of 1 + 1 > 2.

The main purpose of the new intelligent tempering furnace equipment of Tianjin yuantaiderun group is to remove the internal stress in the steel pipe. The methods of removing internal stress include natural aging and artificial aging. Natural aging is that the steel pipe is placed in the open field for more than half a year, and it will form slowly, so as to eliminate or reduce the residual stress. There are two methods of artificial prescription:

① Heat treatment to remove internal stress: heat the steel pipe to 550 ~ 650 ℃ for stress relief annealing, which saves time than natural aging and removes residual stress more thoroughly

② Vibration stress relief: in short, it is to eliminate the stress of steel pipe by vibration. VSR is to apply additional alternating stress or deformation to the workpiece by using the resonance of the workpiece. When the additional alternating stress is superimposed with the residual stress and absorbs energy through the internal friction of the material to reach or exceed a certain threshold value of the material, the workpiece will undergo micro or macro viscoelastic plastic mechanical deformation, so as to reduce and homogenize the residual stress in the workpiece and stabilize its dimensional accuracy.

The square rectangular tube after internal stress relief annealing ensures the mechanical properties, especially in the aspects of yield strength, tensile strength, elongation and impact compressive capacity, and realizes the effect of 1 + 1 > 2.

(the picture shows the effect of 500mm * 500mm * 40MM modified drawing tube annealing heat treatment produced by Yuantai Technology)

(the picture shows the test distortion of modified drawn pipe produced by Yuantai technology after annealing heat treatment)

4、 Engineering performance

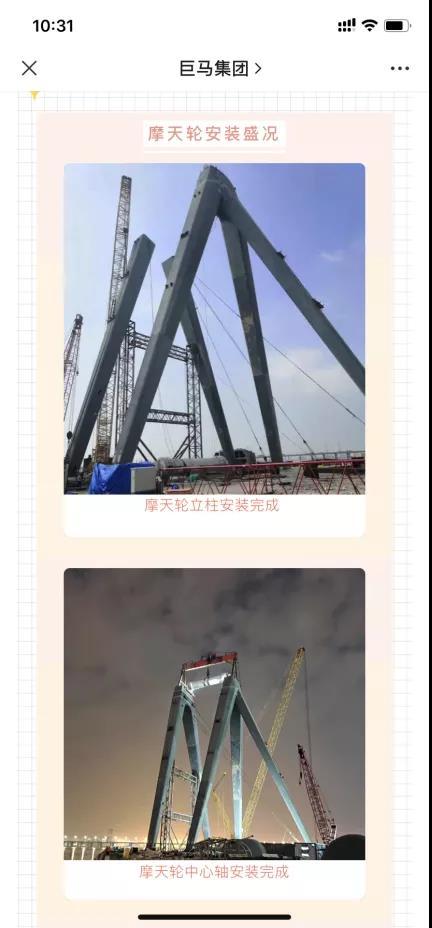

1. The main column of the 128M Ferris wheel of Shenzhen OCT adopts the inclined octagonal tube produced by Yuantai technology

1. The main column of the 128M Ferris wheel of Shenzhen OCT adopts the inclined octagonal tube produced by Yuantai technology

2. The construction of Google tower in Singapore adopts 500mm * 500mm * 36mm modified pipe produced by Yuantai technology, made of s355j2h, with a total of 4000 tons

3. For the establishment of Sichuan Tianfu airport, 90mm * 250mm * 20MM modified pipe produced by Yuantai technology is adopted

4.The headquarters of Beijing Chaoyang aiib was established by adopting 500mm * 520mm * 22mm modified pipe produced by Yuantai technology